Quality

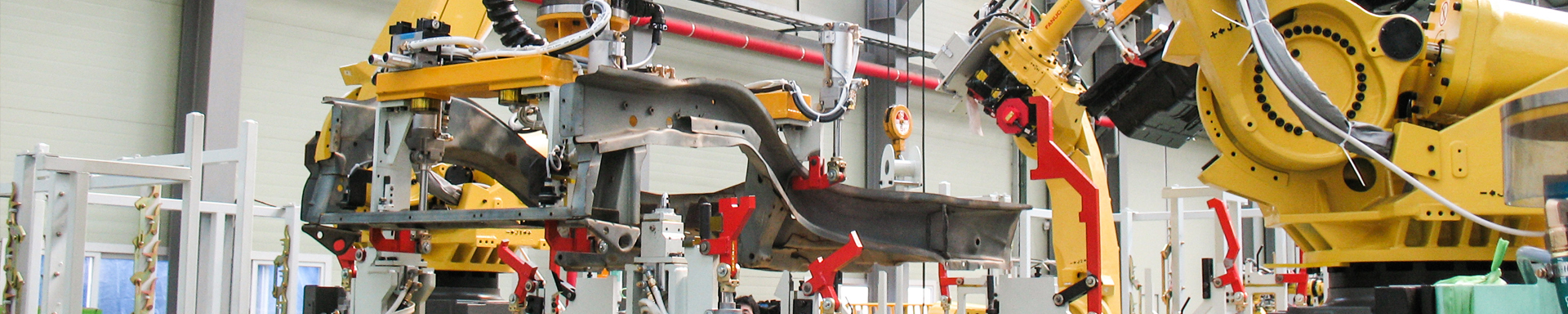

To remain at the helm of the uncompromised quality powertrain component supplier, we have established a global inspection infrastructure where we do the in-depth checking of both mechanical and metallurgical properties of the manufactured components. The Hi-Tech Gears adopts an Integrated Management System approach comprising of Quality Management System, Occupational Health and Safety Management System and Environmental management system. Various TPM initiatives have been implemented across the plants, covering all equipment and areas with the involvement of employees.

To ensure the quality, data is collected, during the manufacturing process, in the form of product or process measurements or readings from various machines or instrumentation. This collected data is used to evaluate, monitor and control a process using Statistical Process Control Methodology. In addition, initial control, setup and tool change approval process, 6-M Controls and process stage wise gate controls are exercised to avert non-conforming parts to get produced or pass into the next stage. A comprehensive quality management system also strives to continually innovate, improve, and advance manufacturing technologies and methodologies to provide optimum solutions to our clientele.

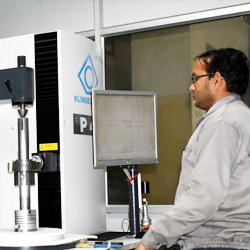

The Hi-Tech Gears adopts robust processes for Quality Assurance which involves supplier assessment and periodic audits, standardized work practices, periodic process and product audits and associates skill assessment and up-gradation. The Hi-Tech Gears boasts a world class inspection infrastructure with state of the art measuring equipment & instruments such as CMM (Carl Zeiss), Gear Analyzer (Klingenberg), Profile Projector, Vickers hardness tester etc. for pre-dispatch inspection. All our manufacturing facilities are ISO/TS certified.